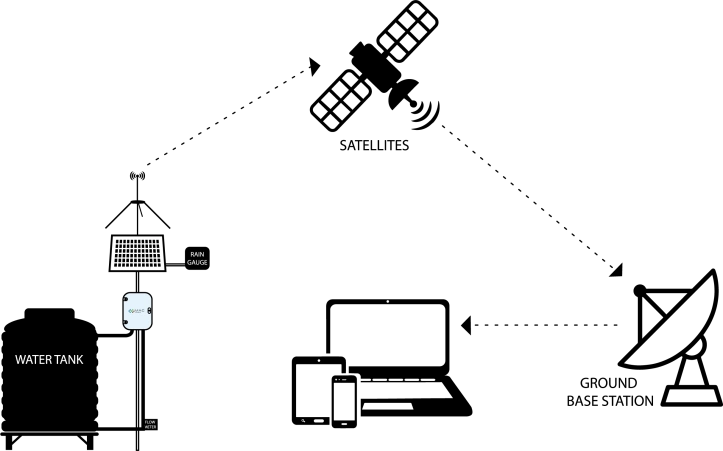

MAC-FMC Satellite

The MAC Systems satellite monitoring and control system has been designed around the latest satellite communications technology. In most cases, hourly data uploads are achieved, however if a satellite link is missed, the data being recorded is stored and uploaded the next satellite pass. The field control and monitoring board (FMC) has been designed to provide the flexibility of being able to read a range of sensors, depending on site requirements. Our standard package accommodates for the most commonly used sensors for stock water monitoring, including water level and flow, with option for rain gauges. The standard package comprises: • Satellite modem and antenna • Field Monitoring and Control board • 20 watt solar panel • Enclosure • 9AH SLA battery Optional mounting solutions includes either a tank top mounting kit and plate and post or separate enclosure and solar panel mounts. Data is stored within the internal memory in the FMC board and depending on the satellite connectivity, data is generally uploaded every hour. If a connection to a satellite is delayed due to the flight path, the data stored within the FMC is uploaded when connection to a satellite is established. This means that even when a satellite pass is missed, no data is lost. Units have in built GPS so the location of field sites can be displayed on a map view. FMC board configuration 3 x Analog Inputs – Note: A1 & A2 can be mapped for relay control (see below) 2 x Relay Outputs (Currently 3 modes – Disabled, Float or Level) – (see below) 1 x Flow Meter input (supports up to 8000 PPS) 1 x Rain Gauge Input 2 x Float Sensor Inputs – (see below) 1 x SDI Input – Currently Supports 80cm EnviroProbe (Soil moisture & temperature). At the present time, manual remote starting and stopping pumps is not yet available due to current limitations with satellite communication timing. Below are the solutions that can be provided for pump control. Relay Control Re: Managing a pump, there are two relay outputs that can be configured in any of the following modes: Mode 0 – Disabled (default mode) Mode 1 – Float Switch • Float Switch to wire to Input 3 (Relay 1) or Input 4 (Relay 2) • When float activated, relay will turn on the pump • When float drops to lower level, relay will turn off stopping the pump • Water level sensor (if fitted) will only feedback water level to portal Mode 2 – Water Level • 0-5vdc Water Level Sensor to wire to Analog 1 (Relay 1) or Analog 2 (Relay 2) • Installer sets Upper & Lower Setpoints on Webpage and scales the input according to the sensor type/range • When level drops to lower setpoint, relay will turn on the pump • When level rises to upper level, relay will turn off stopping the pump • If a float switch is fitted to Input 3 (Relay 1) or Input 4 (Relay 2), it will also turn off the pump if activated (this is an optional safety feature and will not be used to turn on the pump when the float lowers) Maximum Runtime • A Maximum Runtime value can be set for both relays that operates in ALL Modes (0 – No Max time, 1-24 – 1hr to 24hrs max) A1 – A3 Scaling The analog input scaling for A1 to A3 allows the installer to scale the upper and lower operating range of an external analog sensor input For example a 5m 0-5v water pressure sensor in a tank only 2.5m deep would be best scaled to 0 – 2.5v (2.5v representing 100%) Wireless Links A wireless (WCL) link can also be used to turn a remote pump on/off, to do this the installer would simply connect the FMC Relay output to the Input of the WCL Input unit. This option is ideal where the pump is located away from the tank and running cable is not practical or is too far away.